The Perfect Finish Using Starbond Adhesives

There is no exact recipe for applying a CA finish. Talk to 20 different turners and you’ll get 20 different answers on how to lay down the perfect CA finish for your pens. The following is how I use CA glue as a finish for my pens. Cyanoacrylate (CA) glue usually comes in a few different forms. I typically use thin CA as a basecoat, especially for wood pens. Thin CA allows the glue to soak into the grain of the wood. After several coats of thin CA glue, I usually step up to medium CA glue to build up the finish. I reserve thick CA glue for filling gaps in wood pens. For this project, I chose to use a bright and figured piece of maple paired with a bolt-action pen kit. The light color of the wood compliments the gunmetal finish of the hardware. This tutorial will explain how I got a smooth and shiny finish on the pen!

The Materials:

- Starbond Superfast Thin CA Glue (EM-02)

- Starbond Multi-Purpose Medium CA Glue (EM-150)

- Maple Wood

- Bolt Action Pen Kit

- Latex Gloves

- Sandpaper (150-600 grit)

- Finishing Sandpaper (1,500-12,000 grit)

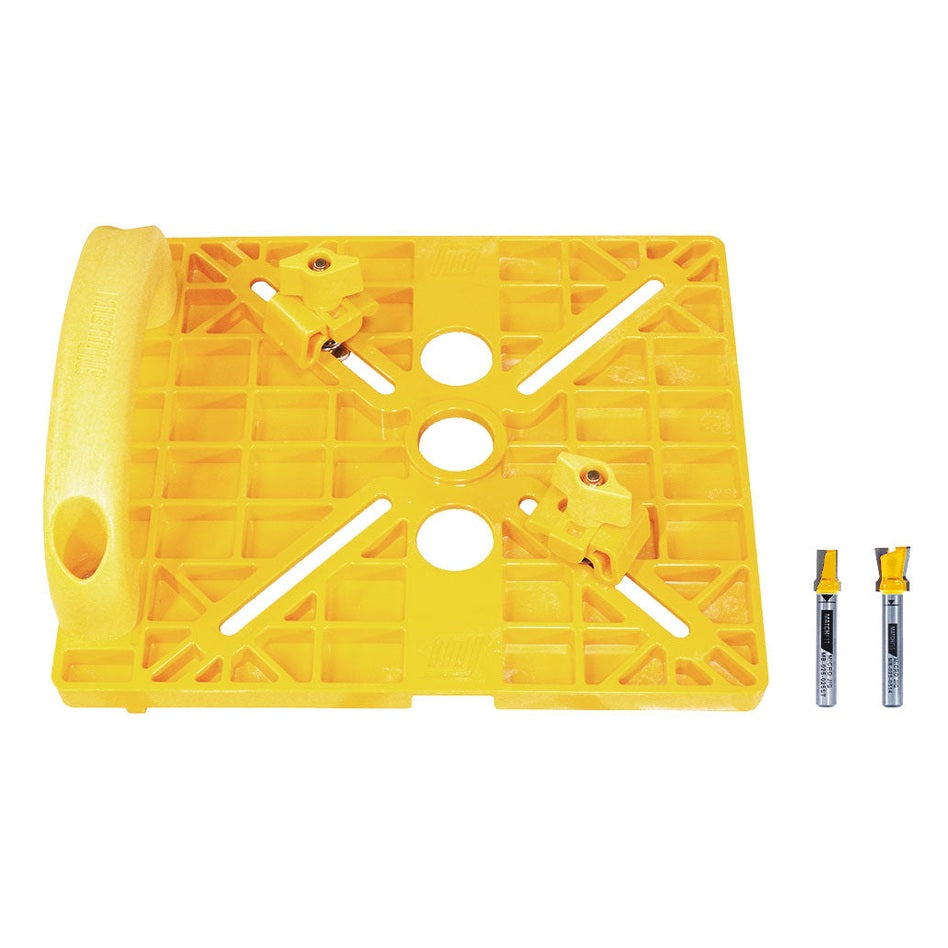

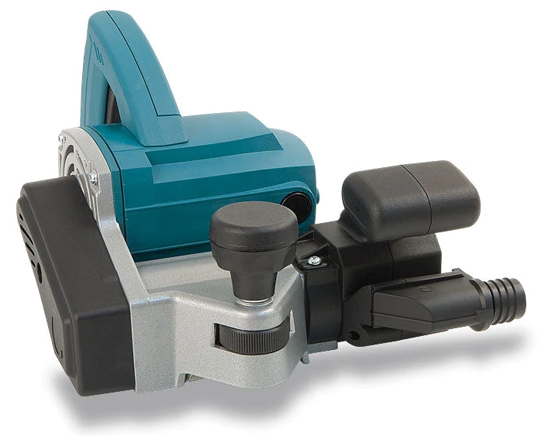

- Turning Tools

- Paper Towels

- Pen Press

- Round File

- Pen Mandrel or Turn-Between-Center Bushings

The Process:

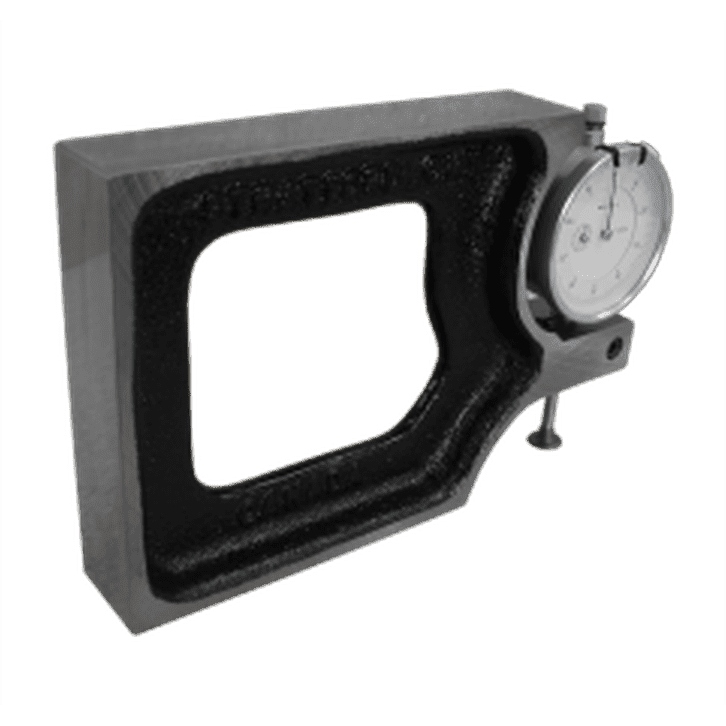

After drilling on the lathe and squaring the ends of my blank to the tube, I usually seal the end of the wood with thin CA glue. Then I’ll re-square both ends just to be sure the blank is square to the kit when I go to put it together. I turn the blank down using a roughing gouge. I shape the blank and ensure a decent fit by using the kit bushings and a micrometer. When I get the blank shaped I’ll sand the piece through at least 600 grit. I typically wet sand acrylic to 1500 if I am using a CA finish. After I finish sanding, I clear the blank of debris using compressed air or a soft cloth. Some people also use denatured alcohol or boiled linseed oil prior to starting the process. Whatever you choose to do, don’t wet sand wood before applying the finish. Moisture is the enemy of a good CA finish because water will expand and contract with temperature changes and can crack your finish weeks or months down the road.

Now you’ll want to change from regular bushings to CA bushings. These can be made from High-Density Polyethylene (HDPE) or bought from most major pen retailers. These will keep your piece from sticking to the bushings. You’ll want to put on your latex gloves now too. Next I’ll roll up a half sheet of paper towel (some brands are already perforated in half) long ways. I use 5-10 drops of Starbond Superfast Thin CA on the tip of the paper towel. I use thin CA first because it penetrates the wood better than thicker glue. To apply the finish, turn the lathe on the slowest speed and lightly rub the end of the CA-soaked paper towel over the blank. I typically only make two or three passes with the paper towel per coat. You do not need to apply a lot of pressure. I place one finger under the towel to lightly apply the finish. Find something that is comfortable for you! The goal here is to get an even finish. After each coat, I cut the end of the paper towel off and use a new section with another 5-10 drops of CA glue. Be careful to apply the finish to the edges of the piece as well.

Some people use accelerator after each coat of CA glue. If you choose to use accelerator, make sure you hold the aerosol at least 8-12 inches away from the piece. I turn the lathe on slow and quickly spray it in one small mist. CA glue only needs a whiff of accelerator to harden. Too much accelerator or holding it too close will cause yellowing and cracking of your finish.

After about 8-10 coats of Thin CA glue, I switch to medium CA to build up the finish. This is applied in a similar fashion except I only use 3-5 drops of glue per coat. You want to build up the finish enough so that you can sand and polish it without sanding through the finish. I use anywhere from 3-8 coats of medium CA. Again, you want to focus on making the finish as even as possible. This will save you time later.

Once your finish has hardened (naturally or via accelerator) you need to smooth it out. This is the step that will take an average CA finish to a top-notch CA finish! When you apply CA using a paper towel, no matter how careful you are, there will be ridges. If you start to sand using higher grits but fail to smooth out the ripples, you will miss scratches in the valleys or the ripples will be very noticeable. To achieve this, I start wet-sanding with 1500 grit on a medium speed. I sand in a circular motion and back and forth, being careful not to stay in one spot too long. When I think the finish is flat, I use another paper towel to dry the piece off. Look for shiny spots on the piece. Shiny spots will show you parts of the blank that didn’t get sanded because they lie in a valley. Sand your piece until it is flat (no shiny places) but be careful not to sand through your finish on the edges. Once you get rid of the shiny places, sand through the grits as normal or buff the piece just like you would an acrylic blank. After you are finished sanding or buffing, carefully inspect your piece under good lighting. CA finishes are tougher to disassemble so you’ll want to be sure it is perfect before you put your pen together.

I hope this quick guide was helpful to you. Remember, there are a hundred different ways to get the perfect finish using Starbond CA glue. Find the methods that work best for you! If you have any questions, feel free to contact me via Instagram or Facebook @The_Pensmiths or by email at Jts3270@gmail.com. Good Luck!