Proudly Canadian Owned

Proudly Canadian Owned& Operated Since 1994

Proudly Canadian Owned

Proudly Canadian Owned Metalworking

Metalworking

Machinery

Machinery

Benders and Notchers

Benders and Notchers

Welding

Welding

Dry Cut Saws

Dry Cut Saws

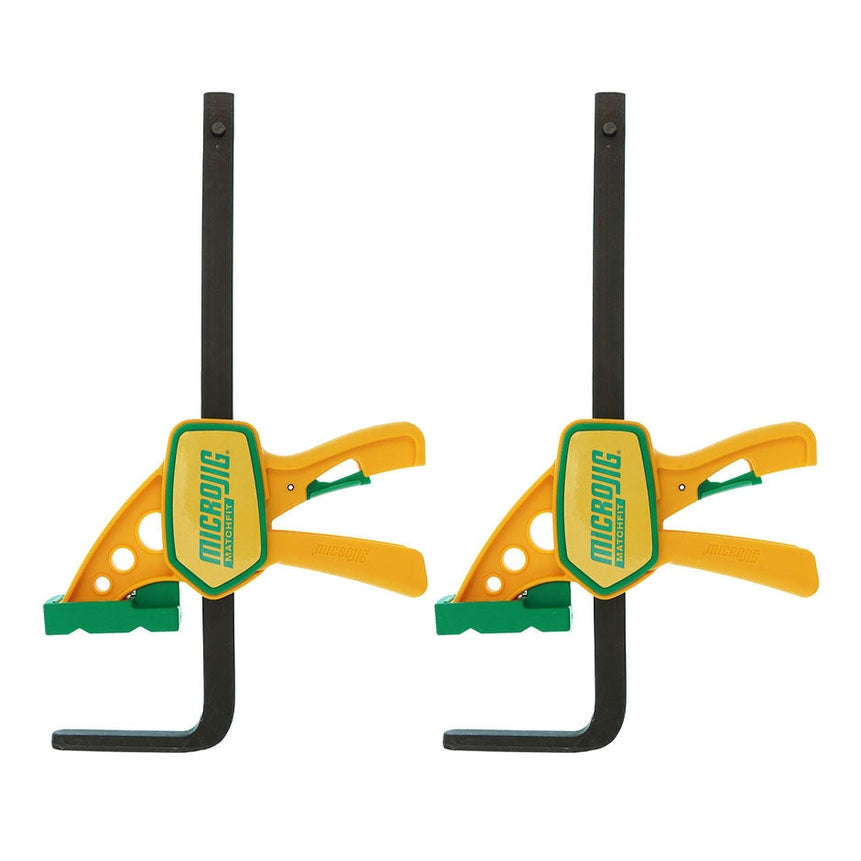

Clamps And Hold Downs

Clamps And Hold Downs

Woodworking

Woodworking

Dust Collection & Air Filtration

Dust Collection & Air Filtration

Accessories

Accessories

Measuring, Marking & Layout

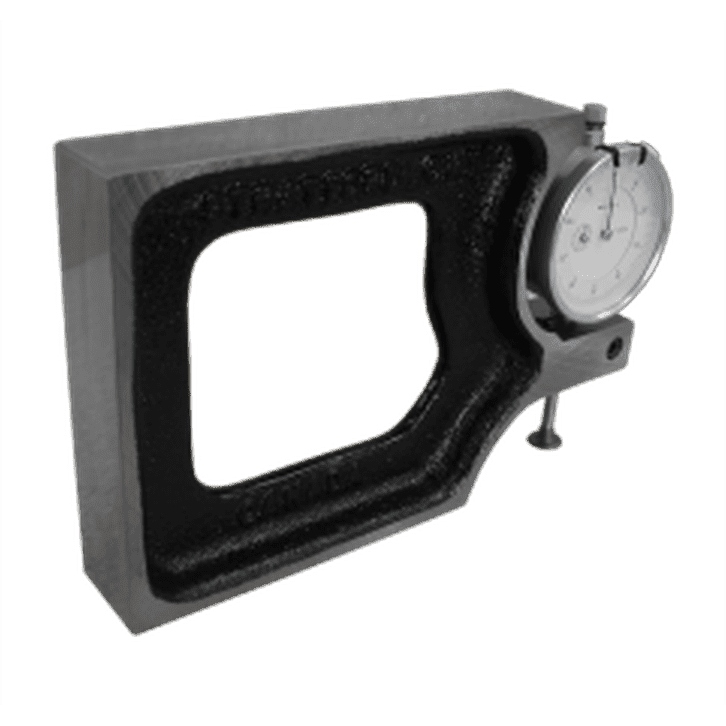

Measuring, Marking & Layout

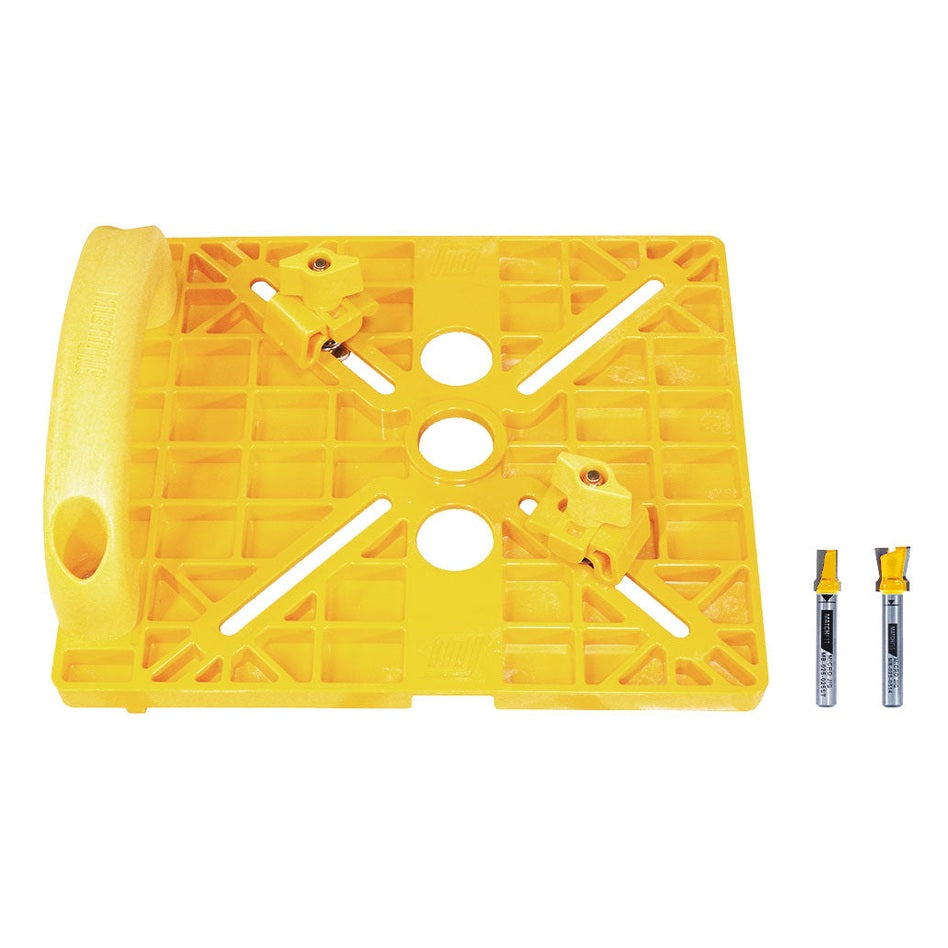

Bits & Blades

Bits & Blades

Supplies

Supplies

Sign up for our newsletter to save $10 off your first order of $50 or more.

Be the first to know about exclusive discounts, new arrivals, sales, and special events. Don’t miss out on the latest updates!

You may check out all the available products and buy some in the shop

Return to shop

Sign up for our newsletter to save $10 off your first order of $50 or more.

No frills and well built, feels like it's going to last a lifetime.

Excellent fine finish sander. Great service from GWS!

Tool works very well

Amazing welder for the price, works great for aluminium. Shipping was quick and well packed. Would recommend for anyone getting into TIG welding. Really a complete kit with the foot pedal and regulator.

The in/outfeed tables provide extra working surface for smaller projects. Projects can be stacked ready to feed into the sander and the outfeed table catches pieces as they come off of the conveyor belt. The extension tables also provide support for longer material both in and out. The fact that they fold down really reduces the foot print when the sander is rolled out of the way for storage.