Proudly Canadian Owned

Proudly Canadian Owned& Operated Since 1994

Proudly Canadian Owned

Proudly Canadian Owned Metalworking

Metalworking

Machinery

Machinery

Benders and Notchers

Benders and Notchers

Welding

Welding

Dry Cut Saws

Dry Cut Saws

Clamps And Hold Downs

Clamps And Hold Downs

Woodworking

Woodworking

Dust Collection & Air Filtration

Dust Collection & Air Filtration

Accessories

Accessories

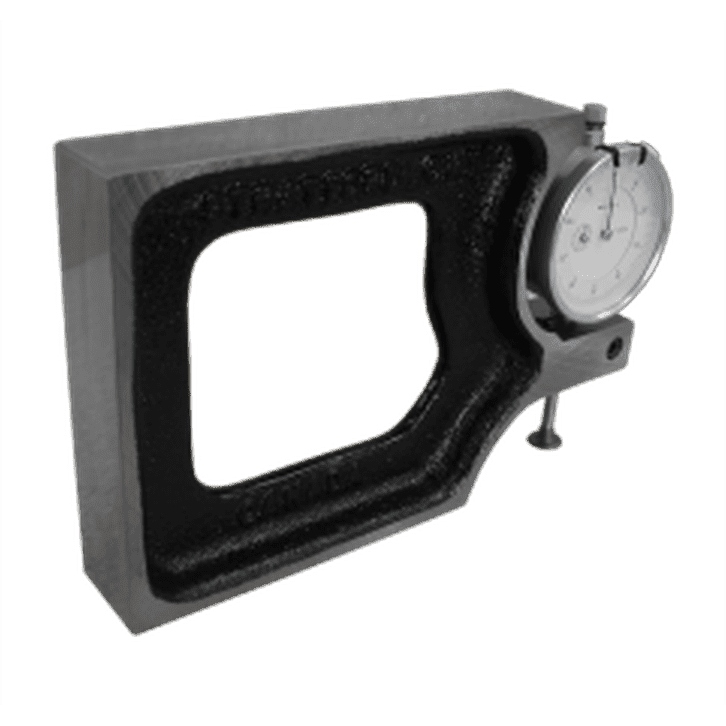

Measuring, Marking & Layout

Measuring, Marking & Layout

Bits & Blades

Bits & Blades

Supplies

Supplies

Sign up for our newsletter to save $10 off your first order of $50 or more.

Be the first to know about exclusive discounts, new arrivals, sales, and special events. Don’t miss out on the latest updates!

You may check out all the available products and buy some in the shop

Return to shop

Sign up for our newsletter to save $10 off your first order of $50 or more.

Great machine at an affordable price.

Great cover fast shipping. Thanks

Great stuff fits well. Thanks

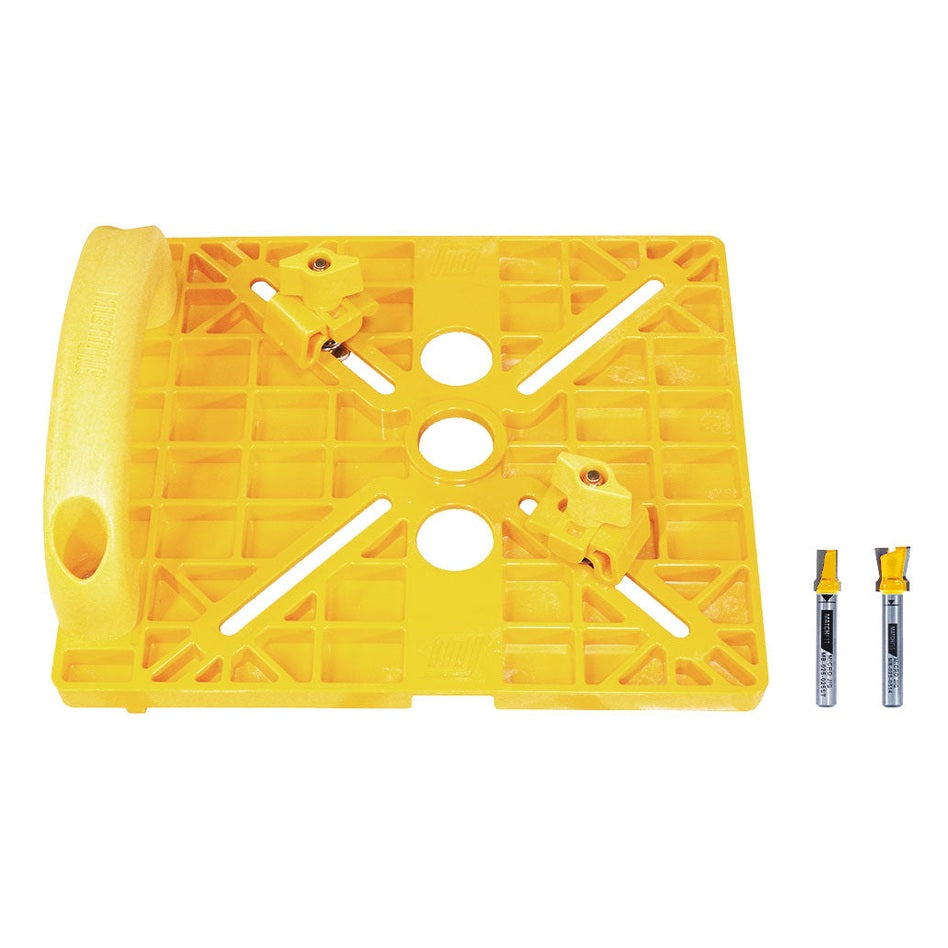

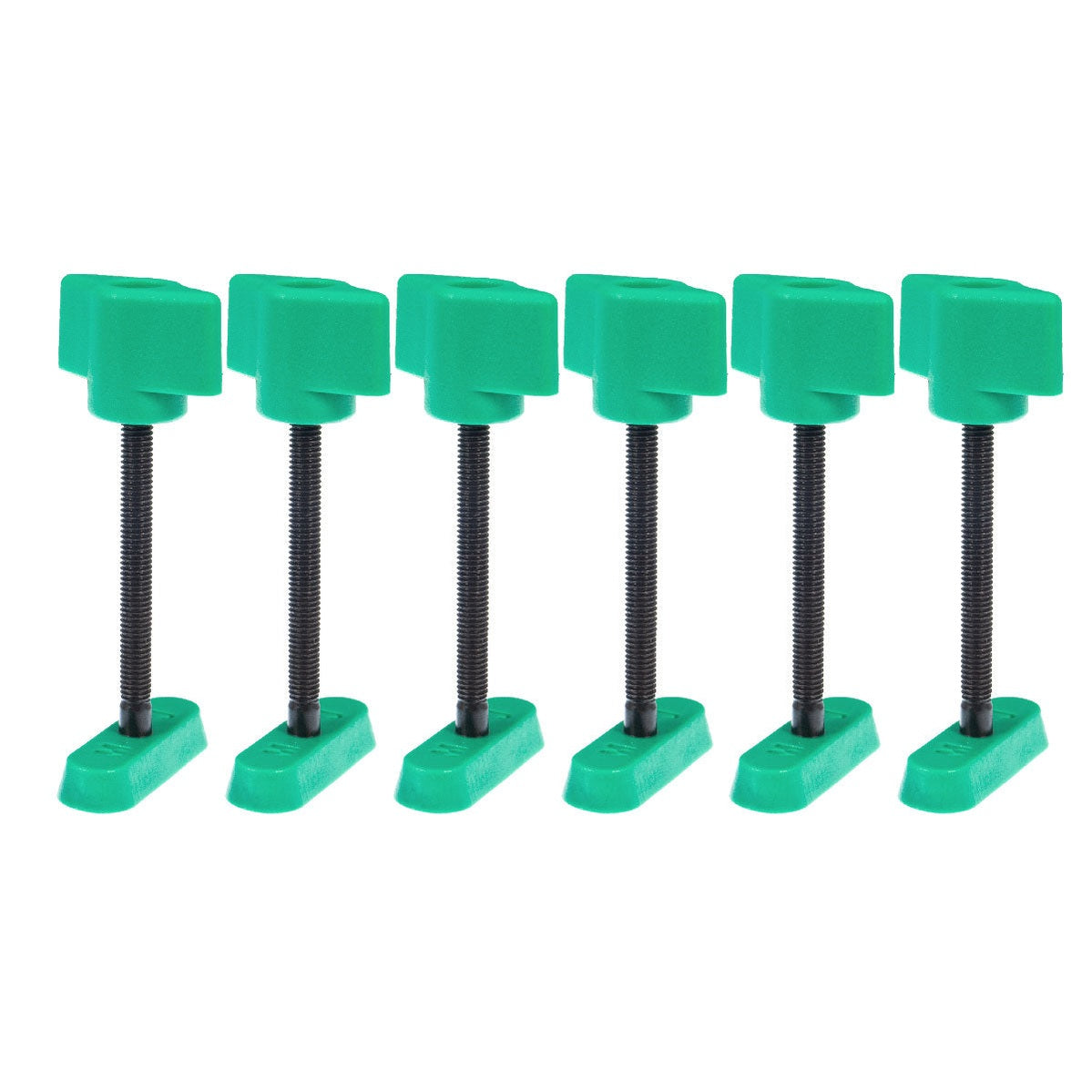

Great product to use as an extra set of hands while putting together cabinets. Highly recommend. I wish the 1/2" clamps were available.

Well written instructions. Easy to use.