RC 1102 Insert V Groove

Proudly Canadian Owned

Proudly Canadian Owned Metalworking

Metalworking

Machinery

Machinery

Benders and Notchers

Benders and Notchers

Welding

Welding

Dry Cut Saws

Dry Cut Saws

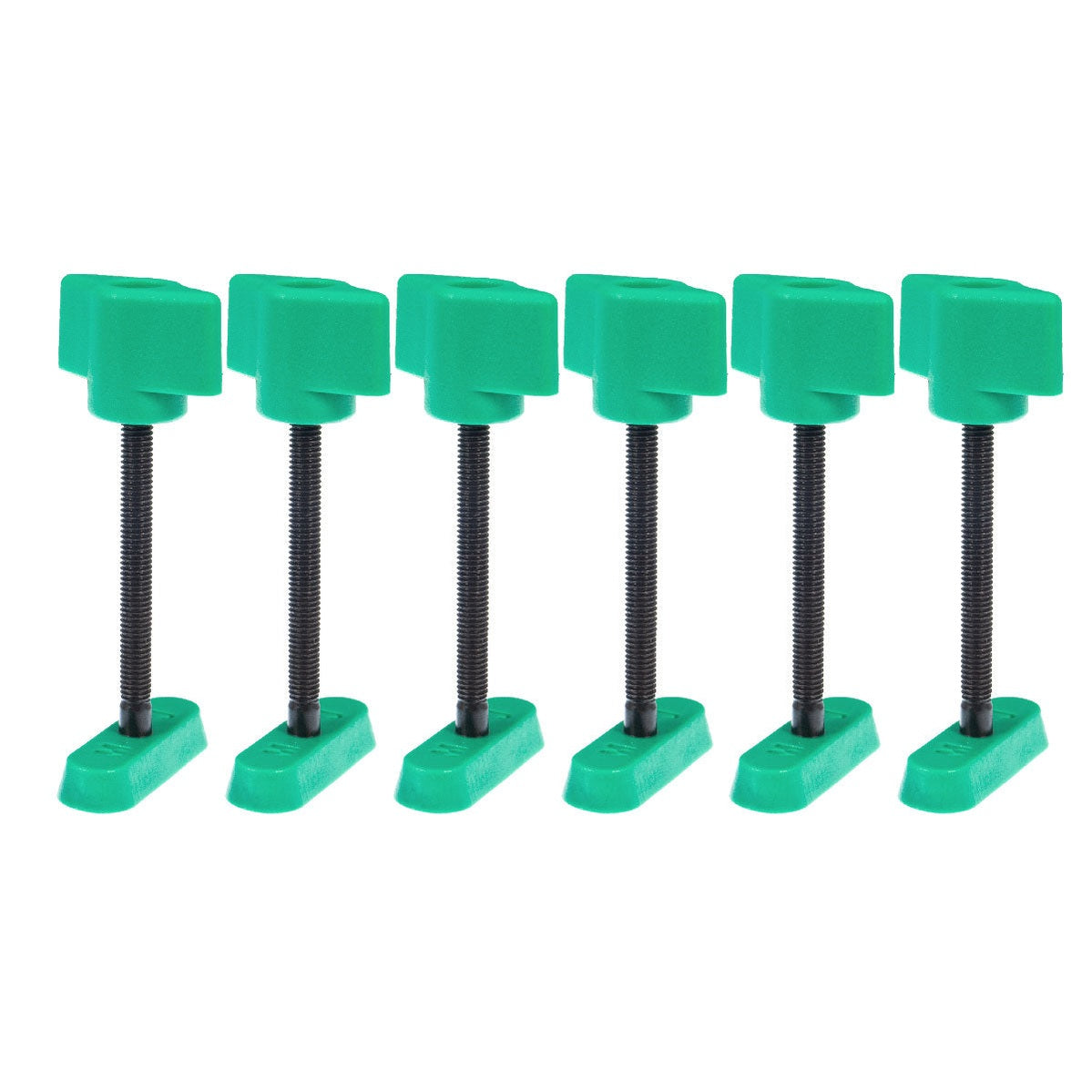

Clamps And Hold Downs

Clamps And Hold Downs

Woodworking

Woodworking

Dust Collection & Air Filtration

Dust Collection & Air Filtration

Accessories

Accessories

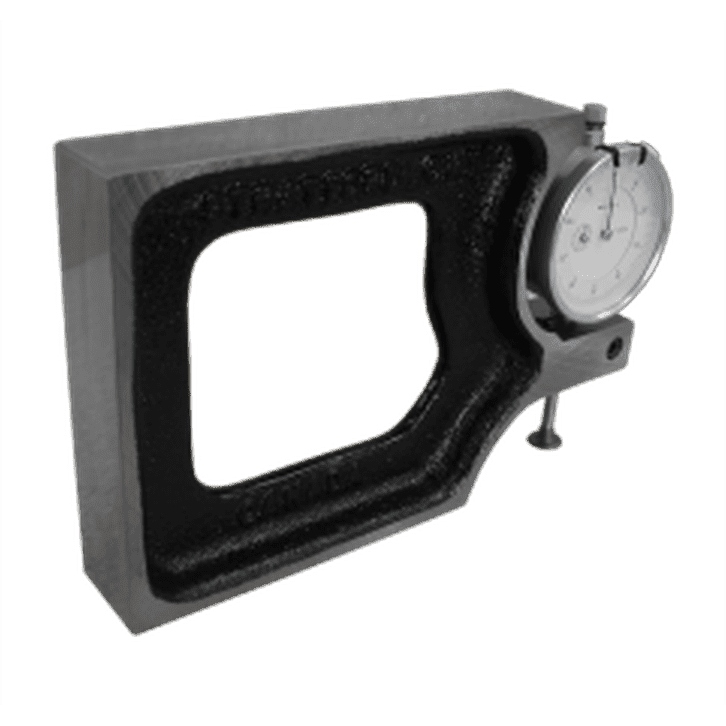

Measuring, Marking & Layout

Measuring, Marking & Layout

Bits & Blades

Bits & Blades

Supplies

Supplies

Sign up for our newsletter to save $10 off your first order of $50 or more.

Be the first to know about exclusive discounts, new arrivals, sales, and special events. Don’t miss out on the latest updates!

You may check out all the available products and buy some in the shop

Return to shop

Sign up for our newsletter to save $10 off your first order of $50 or more.

Love this jig. Great Western Saw was great with my order all the way through. Glad I found this store online. Saved in my favorites!

Exactly what I needed and as advertised. Good price, shipped and delivered quickly by GWS.

At the bottom of the learning curve but have produced a few decent aluminum welds hope it will be a long relationship.

Amazing quality , easy to use . I definitely recommend it .

This 16/32 drum sander is a well-made tool. The accuracy of the final thickness of the material is unbelievable. After a bit of practice changing sandpaper, I can do it in about three minutes. I really like the quick thickness adjust lever. Being able to sand end grain for cutting boards is unbelievable. It does a very quick job of sanding rings I glue up for a blank to turn a bowl on the lathe. There is no snipe nor tearing out of wood on material like maple. The edging for plywood is now smooth and an accurate thickness. The only challenge I have had is to get the feed belt to track in the middle. With some tweaking, I think I now have it. Everything about this Laguna Supermax drum sander is sturdy and precise.