51515 K Solid Carbide CNC Spektra

Proudly Canadian Owned

Proudly Canadian Owned Metalworking

Metalworking

Machinery

Machinery

Benders and Notchers

Benders and Notchers

Welding

Welding

Dry Cut Saws

Dry Cut Saws

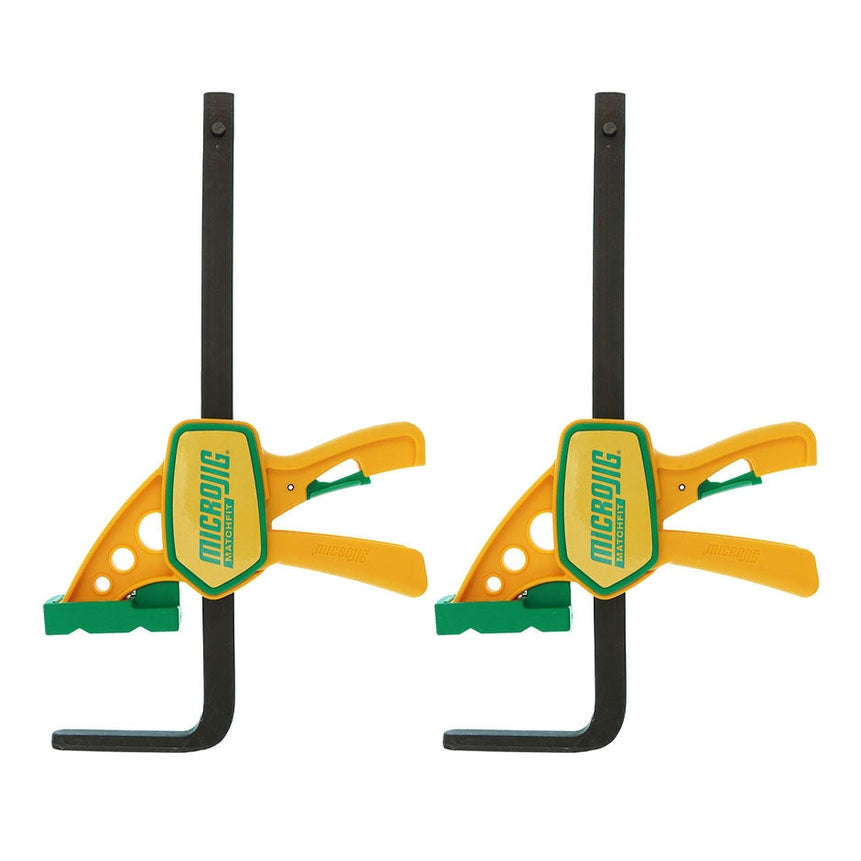

Clamps And Hold Downs

Clamps And Hold Downs

Woodworking

Woodworking

Dust Collection & Air Filtration

Dust Collection & Air Filtration

Accessories

Accessories

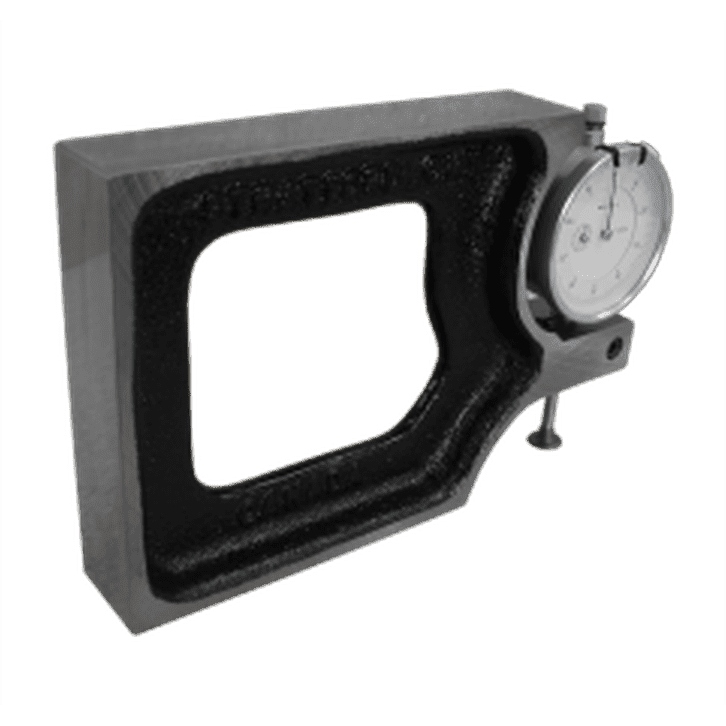

Measuring, Marking & Layout

Measuring, Marking & Layout

Bits & Blades

Bits & Blades

Supplies

Supplies

Sign up for our newsletter to save $10 off your first order of $50 or more.

Be the first to know about exclusive discounts, new arrivals, sales, and special events. Don’t miss out on the latest updates!

You may check out all the available products and buy some in the shop

Return to shop

Sign up for our newsletter to save $10 off your first order of $50 or more.

Missed this part to first review

Purchasing saw from Western saw was easy , Rachel was very professional in her getting products bought paid for and shipped ,as being a rural customer she manage to get shipping figured out painlessly ,will buy again

Great add on for my jointer and table saw

Nice product solves issues with making one so you use it a lot more

Great product. Excellent customer service over the phone. Shipping was clear and efficient.

No frills and well built, feels like it's going to last a lifetime.