No Products in the Cart

The mounted flap wheel KM 613 is the specialist for working in hard-to-reach areas and shines with outstanding performance on such materials as

This small mounted flap wheel has been designed as the perfect complement to all straight grinders and drilling machines with speed control. The unique features of the KM 613 include the soft and flexible flap structure and a constant removal rate. This tools makes it easy to process workpieces that are made up of complex surfaces shapes.

The flexible movements of its flaps provide for additional ventilation on this mounted flap wheel. This allows for cooler grinding, preventing the formation of annealing colours on the workpiece. The KM 613 is used for finishing on metal and is guaranteed to create a brilliant surface finish on stainless steel. Better still, its constant removal rate turns this mounted flap wheel into the ideal abrasive tool for other materials shuch as wood and plastic.

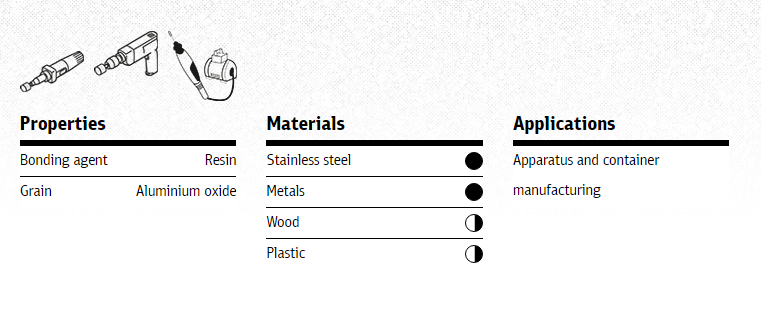

The bonding agent used for the mounted flap wheel KM 613 uses a proven and high-quality synthetic resin. The grain chosen for this product is aluminium oxide. A mounted flap wheel in this excellent quality meets the requirements of demanding applications - whether home improvement or professional users.

The mounted flap wheel KM 613 comes in a large selection of dimensions and grit sizes – from fine to coarse: professional results guaranteed. Small areas are just as easily processed as large profiles. To allow for use in collets, the mounted flat wheel has standard shaft.

Klingspor's abrasive mop products cover a wide field of real-world applications. This includes the use in the industry, for example during fine grinding or the processing of welds. Klingspor offers well-established safety with products that have been tested in accordance with oSa guidelines and the EN 13743 safety standard. To keep safe, the user needs to observe the maximum motor speed and minimum clamping length that are dictated by the exposed shank length.

|

Diameter/Inch

|

Width/Inch

|

Shaft diameter/Inch

|

Grit

|

Vmax m/s

|

Max. RPM

|

Coated Abrasive Type

|

Cat.Number

|

|

1

|

3/8

|

1/4

|

80

|

40

|

30,500

|

LS 309 X

|

278871

|

|

1

|

3/4

|

1/4

|

60

|

40

|

30,500

|

LS 309 X

|

278894

|

|

1

|

3/4

|

1/4

|

80

|

40

|

30,500

|

LS 309 X

|

278895

|

|

1

|

3/4

|

1/4

|

120

|

40

|

30,500

|

LS 309 X

|

278897

|

|

1

|

1/2

|

1/4

|

40

|

40

|

30,500

|

LS 309 X

|

278877

|

|

1

|

1/2

|

1/4

|

60

|

40

|

30,500

|

LS 309 X

|

278878

|

|

1

|

1/2

|

1/4

|

80

|

40

|

30,500

|

LS 309 X

|

278879

|

|

1

|

1/2

|

1/4

|

120

|

40

|

30,500

|

LS 309 X

|

278881

|

|

1

|

1/2

|

1/4

|

180

|

40

|

30,500

|

LS 309 X

|

278882

|

|

1

|

1

|

1/4

|

40

|

40

|

30,500

|

LS 309 X

|

278902

|

|

1

|

1

|

1/4

|

60

|

40

|

30,500

|

LS 309 X

|

278905

|

|

1

|

1

|

1/4

|

80

|

40

|

30,500

|

LS 309 X

|

278907

|

|

1

|

1

|

1/4

|

100

|

40

|

30,500

|

LS 309 X

|

278908

|

|

1

|

1

|

1/4

|

120

|

40

|

30,500

|

LS 309 X

|

278910

|

|

1

|

1

|

1/4

|

180

|

40

|

30,500

|

LS 309 X

|

278912

|

|

1

|

1

|

1/4

|

240

|

40

|

30,500

|

LS 309 X

|

278913

|

|

1

|

1

|

1/4

|

320

|

40

|

30,500

|

LS 309 X

|

278914

|

|

1-1/2

|

3/4

|

1/4

|

60

|

40

|

19,000

|

LS 309 X

|

278956

|

|

1-1/2

|

3/4

|

1/4

|

80

|

40

|

19,000

|

LS 309 X

|

278957

|

|

1-1/2

|

3/4

|

1/4

|

120

|

40

|

19,000

|

LS 309 X

|

278959

|

|

1-1/2

|

1/2

|

1/4

|

40

|

40

|

19,000

|

LS 309 X

|

278946

|

|

1-1/2

|

1/2

|

1/4

|

60

|

40

|

19,000

|

LS 309 X

|

278947

|

|

1-1/2

|

1/2

|

1/4

|

80

|

40

|

19,000

|

LS 309 X

|

278948

|

|

1-1/2

|

1/2

|

1/4

|

120

|

40

|

19,000

|

LS 309 X

|

278950

|

|

1-1/2

|

1/2

|

1/4

|

180

|

40

|

19,000

|

LS 309 X

|

278951

|

|

1-1/2

|

1/2

|

1/4

|

240

|

40

|

19,000

|

LS 309 X

|

278952

|

|

1-1/2

|

1-1/2

|

1/4

|

40

|

40

|

19,000

|

LS 309 X

|

278975

|

|

1-1/2

|

1-1/2

|

1/4

|

60

|

40

|

19,000

|

LS 309 X

|

278976

|

|

1-1/2

|

1-1/2

|

1/4

|

80

|

40

|

19,000

|

LS 309 X

|

278977

|

|

1-1/2

|

1-1/2

|

1/4

|

120

|

40

|

19,000

|

LS 309 X

|

278979

|

|

1-1/2

|

1

|

1/4

|

40

|

40

|

19,000

|

LS 309 X

|

278964

|

|

1-1/2

|

1

|

1/4

|

60

|

40

|

19,000

|

LS 309 X

|

278966

|

|

1-1/2

|

1

|

1/4

|

80

|

40

|

19,000

|

LS 309 X

|

278967

|

|

1-1/2

|

1

|

1/4

|

120

|

40

|

19,000

|

LS 309 X

|

278971

|

|

1-1/2

|

1

|

1/4

|

180

|

40

|

19,000

|

LS 309 X

|

278972

|

|

1-1/2

|

1

|

1/4

|

240

|

40

|

19,000

|

LS 309 X

|

278973

|

|

1-1/2

|

1

|

1/4

|

320

|

40

|

19,000

|

LS 309 X

|

278974

|

|

1-3/16

|

3/16

|

1/4

|

60

|

40

|

25,400

|

LS 309 X

|

278928

|

|

1-3/16

|

3/16

|

1/4

|

120

|

40

|

25,400

|

LS 309 X

|

278930

|

|

1-3/16

|

1

|

1/4

|

60

|

40

|

25,400

|

LS 309 X

|

278924

|

|

1-3/16

|

1

|

1/4

|

120

|

40

|

25,400

|

LS 309 X

|

278927

|

|

2

|

3/8

|

1/4

|

60

|

40

|

15,200

|

LS 309 X

|

278984

|

|

2

|

3/8

|

1/4

|

80

|

40

|

15,200

|

LS 309 X

|

278985

|

|

2

|

3/4

|

1/4

|

40

|

40

|

15,200

|

LS 309 X

|

278999

|

|

2

|

3/4

|

1/4

|

60

|

40

|

15,200

|

LS 309 X

|

279000

|

|

2

|

3/4

|

1/4

|

80

|

40

|

15,200

|

LS 309 X

|

279001

|

|

2

|

3/4

|

1/4

|

100

|

40

|

15,200

|

LS 309 X

|

279002

|

|

2

|

3/4

|

1/4

|

120

|

40

|

15,200

|

LS 309 X

|

279003

|

|

2

|

2

|

1/4

|

40

|

40

|

15,200

|

LS 309 X

|

279031

|

|

2

|

2

|

1/4

|

60

|

40

|

15,200

|

LS 309 X

|

279032

|

|

2

|

2

|

1/4

|

80

|

40

|

15,200

|

LS 309 X

|

279033

|

|

2

|

2

|

1/4

|

120

|

40

|

15,200

|

LS 309 X

|

279035

|

|

2

|

1/2

|

1/4

|

40

|

40

|

15,200

|

LS 309 X

|

278991

|

|

2

|

1/2

|

1/4

|

60

|

40

|

15,200

|

LS 309 X

|

278992

|

|

2

|

1/2

|

1/4

|

80

|

40

|

15,200

|

LS 309 X

|

278993

|

|

2

|

1/2

|

1/4

|

120

|

40

|

15,200

|

LS 309 X

|

278995

|

|

2

|

1-1/2

|

1/4

|

40

|

40

|

15,200

|

LS 309 X

|

279022

|

|

2

|

1-1/2

|

1/4

|

60

|

40

|

15,200

|

LS 309 X

|

279023

|

|

2

|

1-1/2

|

1/4

|

80

|

40

|

15,200

|

LS 309 X

|

279024

|

|

2

|

1-1/2

|

1/4

|

120

|

40

|

15,200

|

LS 309 X

|

279026

|

|

2

|

1-1/2

|

1/4

|

240

|

40

|

15,200

|

LS 309 X

|

279029

|

|

2

|

1

|

1/4

|

40

|

40

|

15,200

|

LS 309 X

|

279008

|

|

2

|

1

|

1/4

|

60

|

40

|

15,200

|

LS 309 X

|

279011

|

|

2

|

1

|

1/4

|

80

|

40

|

15,200

|

LS 309 X

|

279013

|

|

2

|

1

|

1/4

|

100

|

40

|

15,200

|

LS 309 X

|

279015

|

|

2

|

1

|

1/4

|

120

|

40

|

15,200

|

LS 309 X

|

279017

|

|

2

|

1

|

1/4

|

180

|

40

|

15,200

|

LS 309 X

|

279019

|

|

2

|

1

|

1/4

|

240

|

40

|

15,200

|

LS 309 X

|

279020

|

|

2

|

1

|

1/4

|

320

|

40

|

15,200

|

LS 309 X

|

279021

|

|

2-1/2

|

2

|

1/4

|

60

|

32

|

10,150

|

LS 309 X

|

279177

|

|

2-1/2

|

1/2

|

1/4

|

60

|

40

|

12,700

|

LS 309 X

|

279041

|

|

2-1/2

|

1/2

|

1/4

|

80

|

40

|

12,700

|

LS 309 X

|

279042

|

|

2-1/2

|

1-1/2

|

1/4

|

40

|

40

|

12,700

|

LS 309 X

|

279168

|

|

2-1/2

|

1-1/2

|

1/4

|

60

|

40

|

12,700

|

LS 309 X

|

279169

|

|

2-1/2

|

1-1/2

|

1/4

|

80

|

40

|

12,700

|

LS 309 X

|

279170

|

|

2-1/2

|

1-1/2

|

1/4

|

120

|

40

|

12,700

|

LS 309 X

|

279172

|

|

2-1/2

|

1

|

1/4

|

40

|

40

|

12,700

|

LS 309 X

|

279058

|

|

2-1/2

|

1

|

1/4

|

60

|

40

|

12,700

|

LS 309 X

|

279061

|

|

2-1/2

|

1

|

1/4

|

80

|

40

|

12,700

|

LS 309 X

|

279063

|

|

2-1/2

|

1

|

1/4

|

120

|

40

|

12,700

|

LS 309 X

|

279154

|

|

3

|

3/4

|

1/4

|

60

|

40

|

10,150

|

LS 309 X

|

279193

|

|

3

|

3/4

|

1/4

|

80

|

40

|

10,150

|

LS 309 X

|

279194

|

|

3

|

3/4

|

1/4

|

120

|

40

|

10,150

|

LS 309 X

|

279196

|

|

3

|

2

|

1/4

|

40

|

40

|

10,150

|

LS 309 X

|

279212

|

|

3

|

2

|

1/4

|

60

|

40

|

10,150

|

LS 309 X

|

279213

|

|

3

|

2

|

1/4

|

80

|

40

|

10,150

|

LS 309 X

|

279214

|

|

3

|

2

|

1/4

|

120

|

40

|

10,150

|

LS 309 X

|

279216

|

|

3

|

2

|

1/4

|

320

|

40

|

10,150

|

LS 309 X

|

279219

|

|

3

|

1/2

|

1/4

|

40

|

40

|

10,150

|

LS 309 X

|

279233

|

|

3

|

1/2

|

1/4

|

60

|

40

|

10,150

|

LS 309 X

|

279185

|

|

3

|

1/2

|

1/4

|

80

|

40

|

10,150

|

LS 309 X

|

279186

|

|

3

|

1/2

|

1/4

|

120

|

40

|

10,150

|

LS 309 X

|

279236

|

|

3

|

1/2

|

1/4

|

180

|

40

|

10,150

|

LS 309 X

|

279237

|

|

3

|

1/2

|

1/4

|

240

|

40

|

10,150

|

LS 309 X

|

279190

|

|

3

|

1-1/2

|

1/4

|

60

|

40

|

10,150

|

LS 309 X

|

279205

|

|

3

|

1-1/2

|

1/4

|

80

|

40

|

10,150

|

LS 309 X

|

279206

|

|

3

|

1-1/2

|

1/4

|

120

|

40

|

10,150

|

LS 309 X

|

279208

|

|

3

|

1

|

1/4

|

40

|

40

|

10,150

|

LS 309 X

|

279103

|

|

3

|

1

|

1/4

|

60

|

40

|

10,150

|

LS 309 X

|

279105

|

|

3

|

1

|

1/4

|

80

|

40

|

10,150

|

LS 309 X

|

279107

|

|

3

|

1

|

1/4

|

120

|

40

|

10,150

|

LS 309 X

|

279200

|

|

3

|

1

|

1/4

|

180

|

40

|

10,150

|

LS 309 X

|

279201

|

|

3

|

1

|

1/4

|

240

|

40

|

10,150

|

LS 309 X

|

303553

|

|

3

|

1

|

1/4

|

320

|

40

|

10,150

|

LS 309 X

|

303554

|

|

3/4

|

3/4

|

1/4

|

40

|

40

|

38,150

|

LS 309 X

|

303527

|

|

3/4

|

3/4

|

1/4

|

80

|

40

|

38,150

|

LS 309 X

|

303529

|

|

3/4

|

3/4

|

1/4

|

120

|

40

|

38,150

|

LS 309 X

|

303526

|

|

3/4

|

3/4

|

1/8

|

60

|

40

|

38,150

|

LS 309 X

|

303534

|

|

3/4

|

3/4

|

1/8

|

80

|

40

|

38,150

|

LS 309 X

|

303535

|

|

3/4

|

3/4

|

1/8

|

120

|

40

|

38,150

|

LS 309 X

|

303530

|

|

3/8

|

3/8

|

1/8

|

80

|

40

|

76,300

|

LS 309 X

|

303545

|

|

3/8

|

3/8

|

1/8

|

120

|

40

|

76,300

|

LS 309 X

|

303540

|

|

5/8

|

5/8

|

1/8

|

80

|

40

|

50,900

|

LS 309 X

|

303578

|

|

5/8

|

5/8

|

1/8

|

120

|

40

|

50,900

|

LS 309 X

|

303575

|

The benefits at a glanceWide range of applicationsThe abrasive mop is used in a large number of industries and suitable for an abundance of different applications. Possible applications range from the finish grinding of weld seams to finish sanding surfaces on straight and curved work pieces made of various different types of material. Optimal finishPremium-grade grinding flaps with a fan-shape radial arrangement that are firmly anchored by a resign core at the centre of the abrasive mop wheel ensure an optimal adaptation to the contours of the work piece. Klingspor mop wheels provide for very soft and comfortable grinding behaviour and produce identical finishes from the first to the last work piece. Proven safetyEvery Klingspor abrasive mop has been tested according to the guidelines of the oSa directives and is guaranteed to comply with European safety standard EN 13743. |

Applications

|

The abrasive mop wheel‘s construction makes it perfect for achieving a smooth surface finish. The abrasive mop wheel achieves a significantly smoother surface finish com- pared to that of a belt grinder. When choosing a grit size please select a grit size that is 2-3 sizes rougher than that used with a belt grinder.

|

Abrasive belt 40 grit |

Abrasive mop wheel 40 grit |

To be able to work at the optimal cutting rate (38-42 m/s) the selection of the abrasive mop diameter for machines, that are not equipped with RPM setting functionality, is based on the set RPM. Machines that are equipped with RPM setting functionality are to be set according to the abrasive mop wheel diameter settings.

Attention! Before turning the machine on please check that the pre-set RPM does not exceed the maximum abrasive mop RPM setting.

Please refer to the adjoining table for the correct abrasive mop diameter settings for the optimal RPM range. If the abrasive mop wheel is used at the optimal RPM setting, the grinding flaps stand up straight as result of the centrifugal forces around the core and provide optimum abrasive mop wheel grinding properties. Only the edges of the grinding flaps are subjected to wear and tear. This results in the use of new and sharper grits. This ensures uniform stock removal and surface finish – from the first to the last work piece. Suboptimal RPM settings (too low) result in the incorrect positioning of the grinding flap as a result of tool / grinding pressure. This results in wear and tear on the grit side of the grinding flaps, and the area the abrasive mop wheel grinds is too large, which in turn results in higher friction between the workpiece and the grinding flaps. Consequently the workpiece and abrasive mop wheel are subjected to a higher thermal load and a higher degree of wear and tear on the grinding flaps. Ultimately, this can result in the failure of the abrasive mop wheel and damaged grinding flaps.

Maximum RPM:

Klingspor SM 611 abrasive mop wheels are certified for widths of ≤ 100 mm and maximum revolutions per minute of 50 m/s.

Optimal cutting rate: The abrasive mop wheel’s optimum performance range is a cutting rate between 38-42 m/s.

| Mop-ø [mm] | Recommended RPM range [min-1] (38-42 m/s) |

|---|---|

| 100 | 7.300–8.000 |

| 140 | 5.200–5.700 |

| 165 | 4.400–4.800 |

| 200 | 3.650–4.000 |

| 250 | 2.900–3.200 |

| 300 | 2.400–2.650 |

| 350 | 2.100–2.300 |

| 380 | 1.900–2.100 |

| 410 | 1.750–1.950 |

| 480 | 1.500–1.650 |

| 510 | 1.400–1.550 |

The surface finish is dependent upon a wide range of process parameters. The table below illustrates the different influencing factors and their affect on the grinding result.

| Influencing factor | Stock removal* | Surface finish | Service life | |

| Cutting rate | high | increases | finer | shorter |

| low | decreases | rougher | longer | |

| Tool / grinding pressure | high | increases | rougher | shorter |

| gering | decreases | finer | longer | |

| Grit size | rough | increases | rougher | shorter |

| fine | decreases | finer | longer | |

| Grinding Aids (oils, lubricants) |

without | increases | rougher | shorter |

| with | decreases | finer | longer | |

* Note: the essential parameters that affect the stock removal rate is the selection of a rougher (more stock removal) or finer (less stock removal) grit.