No Products in the Cart

This abrasive mop disc is a popular choice for edges and surface work on stainless steel and steel

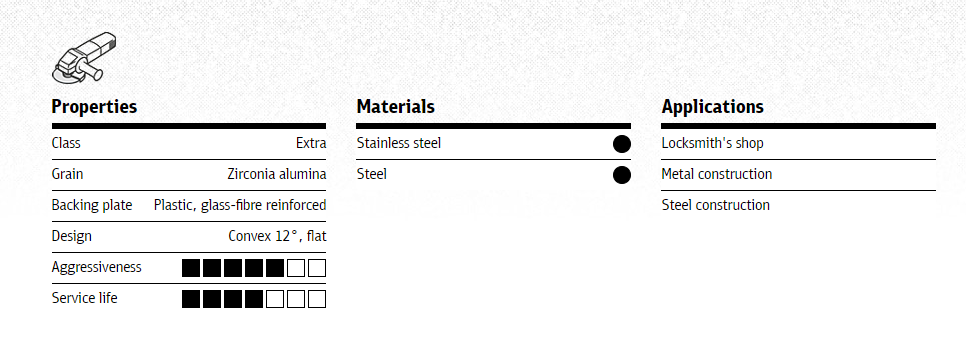

The abrasive mop disc SMT 325 Extra is made up of a plastic backing plate Suitable for a wide range of use cases, the flap disc is available both as a flat and a convex type. The convex type delivers higher stock removal per unit of time compared to the flat type. This quality makes the convex type of this flap disc a particularly well-suited option for work on edges and seams. Meanwhile, the flat type is the better choice for grinding flat surfaces.

The Klingspor abrasive mop discs included in the Extra product line are marked by their unsurpassed price-performance ratio. When used for work on steel and stainless steel, the abrasive discs deliver excellent abrasive performance at minimum tool pressure without the risk of glazing. The self-sharpening zirconia alumina is responsible for the excellent service life of this flap disc. It can be combined with any standard angle grinder of all performance classes. Users must, however, observe the product's permissible circumferential speed in m/s. This specification is printed on the disc.

plastic backing plate forms the basis of this abrasive disc and provides for optimum force transmission onto the workpiece to be processed. Coated with zirconia alumina, the abrasive flaps are connected to the backing plate with an extremely secure bond that results from a special manufacturing process. Exceeding the requirements set out in safety standard EN 13743, this bonding is guaranteed to increase safety. Despite this enhanced safety, it is vital for the user to wear the proper personal protective equipment when working with the abrasive mop disc. This equipment should be comprised of eye and hearing protection, gloves and a dust mask. Also essential is refraining from working close to combustible materials.

|

Diameter/Inch

|

Bore/Inch

|

Form

|

Grit

|

Vmax m/s

|

Max. RPM

|

Coated abrasives Type

|

Structural Shape

|

Holding device

|

Cat.Number

|

|

4-1/2

|

7/8

|

|

40

|

80

|

13,300

|

CS 455 X

|

flat

|

|

321653

|

|

4-1/2

|

7/8

|

|

40

|

80

|

13,300

|

CS 455 X

|

flat

|

X-LOCK

|

351281

|

|

4-1/2

|

7/8

|

|

60

|

80

|

13,300

|

CS 455 X

|

flat

|

|

321655

|

|

4-1/2

|

7/8

|

|

60

|

80

|

13,300

|

CS 455 X

|

flat

|

X-LOCK

|

351280

|

|

4-1/2

|

7/8

|

|

80

|

80

|

13,300

|

CS 455 X

|

flat

|

|

321657

|

|

4-1/2

|

7/8

|

|

80

|

80

|

13,300

|

CS 455 X

|

flat

|

X-LOCK

|

351279

|

|

4-1/2

|

7/8

|

|

40

|

80

|

13,300

|

CS 455 X

|

convex

|

|

321659

|

|

4-1/2

|

7/8

|

|

60

|

80

|

13,300

|

CS 455 X

|

convex

|

|

321661

|

|

4-1/2

|

7/8

|

|

80

|

80

|

13,300

|

CS 455 X

|

convex

|

|

321663

|

|

5

|

7/8

|

|

40

|

80

|

12,200

|

CS 455 X

|

flat

|

|

321654

|

|

5

|

7/8

|

|

40

|

80

|

12,200

|

CS 455 X

|

flat

|

X-LOCK

|

351278

|

|

5

|

7/8

|

|

60

|

80

|

12,200

|

CS 455 X

|

flat

|

|

321656

|

|

5

|

7/8

|

|

60

|

80

|

12,200

|

CS 455 X

|

flat

|

X-LOCK

|

351277

|

|

5

|

7/8

|

|

80

|

80

|

12,200

|

CS 455 X

|

flat

|

|

321658

|

|

5

|

7/8

|

|

80

|

80

|

12,200

|

CS 455 X

|

flat

|

X-LOCK

|

351276

|

|

5

|

7/8

|

|

40

|

80

|

12,200

|

CS 455 X

|

convex

|

|

321660

|

|

5

|

7/8

|

|

60

|

80

|

12,200

|

CS 455 X

|

convex

|

|

321662

|

|

5

|

7/8

|

|

80

|

80

|

12,200

|

CS 455 X

|

convex

|

|

321664

|

The benefits at a glanceOptimised performanceThe abrasives used have also been engineered to work with high-speed angle grinders (80 m/s) and are designed to offer a wide range of possible applications. The optimised arrangement of the grinding flaps ensures first-rate grinding performance, long service lives and optimised utilisation to the end. Sustained high performanceThe cloth flaps are coated with zirconia alumina, ceramic or aluminium oxide and spaced equally on the backing plate. The optimised cloth-reinforced backing guarantees the operator a fresh grit and, thus, consistent removal throughout the entire work process. Extraordinary stabilityThe backing plates included in our SMT range are made of glass fibre or glass-fibre reinforced plastic. They are extremely hard-wearing and deliver optimal power transmission to the work piece. Tried-and-tested safetyA special manufacturing process ensures an exceptionally strong bond between baking plate and grinding flaps and produces a level of break resistance that easily exceeds the provisions of the oSa and EN 13743 standards. |

Applications

|