No Products in the Cart

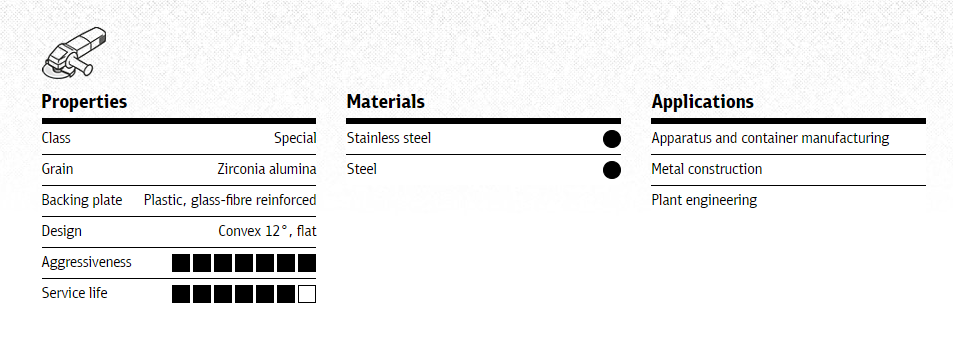

The flap disc SMT 925 Special stands out with its noticeably higher abrasive performance and excellent service life. This abrasive has been designed for use on such materials as

When used on these surfaces, the product will perform at its best and convince even the most discerning users. The product is an abrasive mop disc that is grouped in the performance class Special. Products categorized in this class are marked by their particular aggressiveness and exceptional service life. These attributes are appreciated to the same degree by experienced professional users and hobby craftsmen working on a challenging do-it-yourself project. Its singular abilities make this top-tier product the flap disc of choice for anyone who wishes to achieve the best possible results.

This abrasive mop disc owes its high removal rate to its abrasive grain made of zirconia alumina. The SMT 925 Special truly shines when it is combined with powerful angle grinders. Its plastic backing plate excels with incredible durability even under intense use. Available in different grit sizes ranging from fine to coarse, the product has been designed for a high number of revolutions.

Klingspor makes this flap disc available to their customers as a flat and a convex model. Convex abrasive mop discs grinds with a smaller abrasive surface area. The resulting point-by-point processing lets the user attain greater stock removal per unit of time. This type of processing is ideal for work on edges and weld seams. Flat type, on the other hand, use a much wider surface area of abraisive, which makes them ideal for flat and surface grinding. Klingspor's line of Special abrasive mop discs offers the right abrasive disc for any application. Designed for use in trade and industry, this high-performance products marry superior performance with an exceptional service life even under continuous heavy use. Available in a wide range, the flap disc SMT 925 Special is a dependable abrasive for an extensive range of applications.

|

Diameter/Inch

|

Bore/Inch

|

Form

|

Grit

|

Vmax m/s

|

Max. RPM

|

Coated abrasives Type

|

Structural Shape

|

Cat.number

|

|

4-1/2

|

7/8

|

|

36

|

80

|

13,300

|

CS 461 X

|

flat

|

321668

|

|

4-1/2

|

7/8

|

|

40

|

80

|

13,300

|

CS 461 X

|

flat

|

321670

|

|

4-1/2

|

7/8

|

|

60

|

80

|

13,300

|

CS 461 X

|

flat

|

321674

|

|

4-1/2

|

7/8

|

|

80

|

80

|

13,300

|

CS 461 X

|

flat

|

321677

|

|

4-1/2

|

7/8

|

|

40

|

80

|

13,300

|

CS 461 X

|

convex

|

321714

|

|

4-1/2

|

7/8

|

|

60

|

80

|

13,300

|

CS 461 X

|

convex

|

321715

|

|

4-1/2

|

7/8

|

|

80

|

80

|

13,300

|

CS 461 X

|

convex

|

321716

|

|

5

|

7/8

|

|

40

|

80

|

12,200

|

CS 461 X

|

flat

|

321671

|

|

5

|

7/8

|

|

60

|

80

|

12,200

|

CS 461 X

|

flat

|

321675

|

|

5

|

7/8

|

|

80

|

80

|

12,200

|

CS 461 X

|

flat

|

321678

|

|

5

|

7/8

|

|

40

|

80

|

12,200

|

CS 461 X

|

convex

|

321719

|

|

5

|

7/8

|

|

60

|

80

|

12,200

|

CS 461 X

|

convex

|

321720

|

|

5

|

7/8

|

|

80

|

80

|

12,200

|

CS 461 X

|

convex

|

321721

|

|

7

|

7/8

|

|

24

|

80

|

8,500

|

CS 461 X

|

flat

|

321667

|

|

7

|

7/8

|

|

36

|

80

|

8,500

|

CS 461 X

|

flat

|

321669

|

|

7

|

7/8

|

|

40

|

80

|

8,500

|

CS 461 X

|

flat

|

321672

|

|

7

|

7/8

|

|

60

|

80

|

8,500

|

CS 461 X

|

flat

|

321676

|

The benefits at a glanceOptimised performanceThe abrasives used have also been engineered to work with high-speed angle grinders (80 m/s) and are designed to offer a wide range of possible applications. The optimised arrangement of the grinding flaps ensures first-rate grinding performance, long service lives and optimised utilisation to the end. Sustained high performanceThe cloth flaps are coated with zirconia alumina, ceramic or aluminium oxide and spaced equally on the backing plate. The optimised cloth-reinforced backing guarantees the operator a fresh grit and, thus, consistent removal throughout the entire work process. Extraordinary stabilityThe backing plates included in our SMT range are made of glass fibre or glass-fibre reinforced plastic. They are extremely hard-wearing and deliver optimal power transmission to the work piece. Tried-and-tested safetyA special manufacturing process ensures an exceptionally strong bond between baking plate and grinding flaps and produces a level of break resistance that easily exceeds the provisions of the oSa and EN 13743 standards. |

Applications

|